■ Dry Etch Mechanism

- 보통 음극 쪽에 웨이퍼를 둔다.

- 물리적 식각 : +이온 (Sheath 부분에서 가속되면서 충돌) => 비등방성(이방성) 식각

- 화학적 식각 : 라디칼 (박막 표면과 표면 반응) => 등방성 식각

=> 적절한 혼합을 통해 식각의 방양성에 있어 넓은 수준의 자유도(Control이 쉬움)를 가짐.

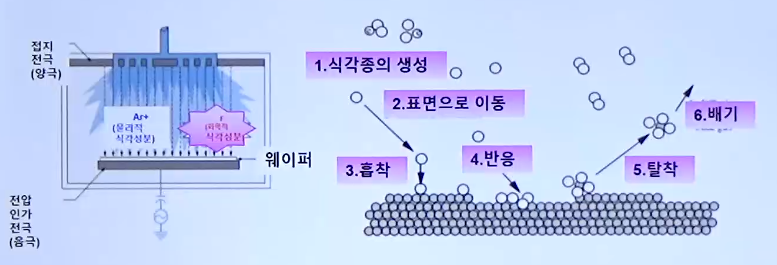

- 메커니즘

ex) SiO2 Etch

1) 원자 및 분자의 여기, 해리, 이온화

CHF3 -> H, CF3, e

2) 흡착 : 필름 표면에서 흡착

3) 반응 : 필름과 이온에 의한 해리와 결합으로 반응 생성물의 형성

4) 탈착 : 반응 생성물의 탈착

[건식 식각 원리]

1) 화학적 결합에 관여하는 가스를 챔버에 유입, 외부 교류 RF 전원으로 플라즈마 발생 유발

2) 플라즈마 상태로 유입된 가스는 이온, 라디칼, 전자, 원자 형태로 활성화

3) 라디칼은 웨이퍼 상에서 화학적 결합으로, 이온은 물리적 충돌에 의해 원자를 떼어냄 (Sheath 영역에서)

4) 플라즈마 건식 식각 = 화학적 방식 + 물리적 방식 => RIE

5) 화학 결합 과정에서 생성된 잔류 가스는 진공 펌프로 외부 배기

■ Dry Etch 종류

1) Plasma Etching (화학적)

- reactive gas plasma, low energy ion bombardment

- 등방성 식각, 선택비 우수

(식각률 : Poly SI > SiN > thermal SiO2(밀도 높다))

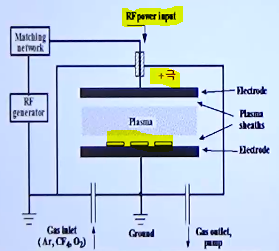

- RF Power를 양극(anode)에 결합한 방식

2) Reactive Ion Etching (RIE) (화학적+물리적)

- 라디칼 + 이온(F+, CF3+)

- reactive gas plasma, high energy ion bombardment

- 비등방성, 선택비 우수

- RF Power를 Capacitor에 달아서 시료를 위에 접속한 음극(Cathode)에 결합한 방식

- 하위전극 층에 Sheath 층 형성 (+이온들이 -쪽인 W/F로)

- 문제점 : 가속된 이온에 의해 기판이 손상 받기 쉬움

3) Sputtering Etching (물리적)

- Inert gas plasma, high energy ion bombardment

- 비등방성 식각

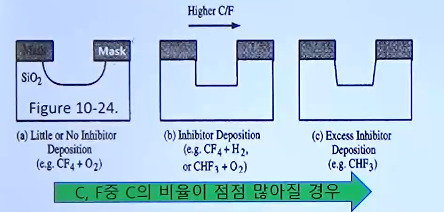

4) 이온강화 억제제 식각 (Ion enhanced inhibitor etching)

- RIE 중 식각제의 반응성이 너무 높은 경우 이방성이 잘 확보되지 않는 경우

-> 피 식각 박막의 측벽에 식각 억제 물질을 피복시킴으로써 개선.

- 반응 기체와 함께 첨가제를 주입 (화학적 식각을 방해하는 식각 억제제 물질을 형성)

- 억제제 형성 -> 이온에의한 바닥면 식각 -> 라디칼에 의한 바닥면의 화학적 식각 반복

- 그 결과 수직에 가까운 형상(Profile)을 얻을 수 있음.

- 억제제는 주로 CxFy 기체의 반응으로부터 생성되는 고분자 물질 -> 억제제는 적절한 유량의 O2에 의해 CO2 형태로 제거

■ Dry Etch 공정에 영향을 미치는 요인

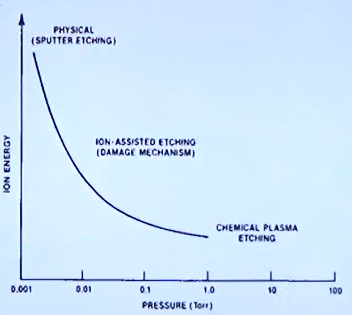

1) 공정 압력

- 공정 압력에 따라 플라즈마 밀도와 이온 충돌 에너지 변화 (파센 곡선)

- 압력이 높으면 화학적 반응/ 압력이 낮으면 물리적 식각

2) RF 파워

- 플라즈마 발생 비율, 밀도, 충돌 에너지 등에 따라 식각 속도 변화

- Sheath potential/Ion energy에 영향

- 식각종의 밀도에 영향

- 파워가 높아지면 일반적으로 식각 속도 증가

3) 기판 온도

- 식각 대상물질의 온도에 따라 식각 속도 변화 (온도 높아지면 E.R 높아짐)

- 화학적 식각의 중요 요소 k(T) = A(T) exp(-Ea/RT)

4) 가스 종류

- 식각에 사용되는 가스의 종류

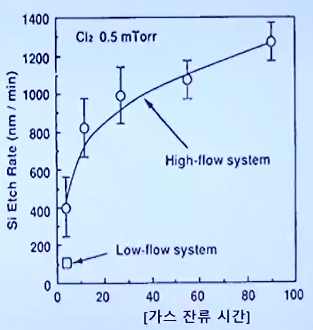

5) 가스 유량

- 가스의 흐름, 식각 후 배기 속도

- 화학종들의 잔류 시간을 결정하는 요소

(Flow속도가 높으면 잔류시간이 줄어든다. => 잔류시간이 길어지면 식각 속도가 빨라진다)

■ Dry Etch 공정 요구사항

1) 높은 Mask(PR or HM)/Film 선택비 (특히 contact open에서 중요)

2) Anisotropy (비등방성)

3) 높은 Etch Rate (Throughput) (Cu/Pt 식각 등에서 문제)

4) 높은 ★Uniformity (in wafer, wafer-wafer, run-run) (WIW, WTW, Lot to Lot)

=> 웨이퍼가 커지다보니 웨이퍼 내에서, 웨이퍼 끼리, Lot 끼리도 Etch Rate가 똑같아야 한다!(★ 재현성 중요!)

5) 낮은 Damage (소자 집적도 증가에 따라 중요성 커짐)

6) Cleaness (수율에 직접적인 영향, process induced particle 문제 됨)

7) Mask제거 용이 (PR-Ashing strip, Hard mask)

8) Safety (식각에 사용되는 가스들은 대부분 유독, 발암물질)

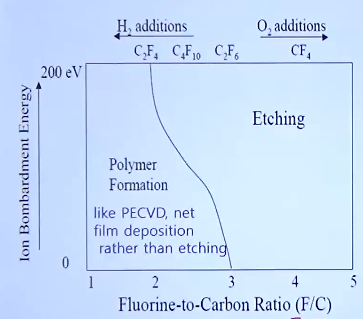

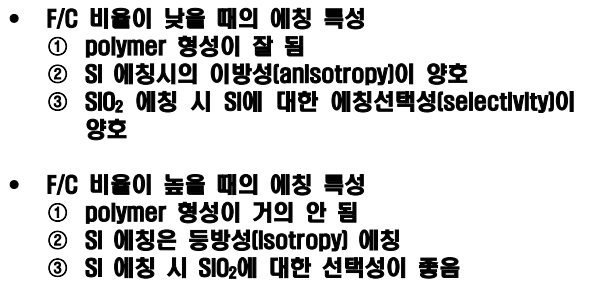

■ Carbon/Fluorine Ratio의 영향

C/F Ratio는 Plasma etch시 Polymer 발생량(inhibitor)과 관련이 있으며, Etch rate에도 영향을 미침

=> C의 비율이 많아질 경우 측벽에 Polymer 많아짐. (inhibitor)

- Ar+은 불활성 가스이고 화학적 반응이 없어 패턴 바닥의 inhibitor 제거에 용이하다

- High bias voltage(400~500eV)는 바닥의 inbitor 제거로 수직 식각 촉진

- F/C 가스 비율 감소는 SiO2와 Si의 선택비를 향상시킴. (?)

- 측벽의 Polymer inhibitor 제거는 O2 또는 CF4로

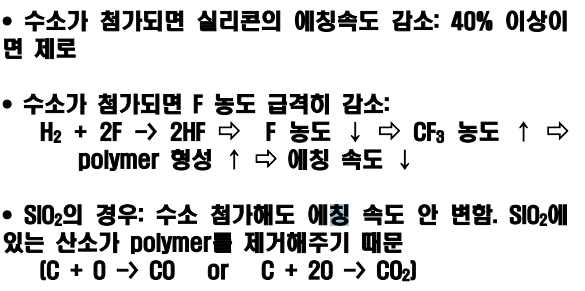

[Case 1 : C가 많은 경우-Polymerization]

- C가 많아지면(F/C Ratio가 낮으면) Polymer inhibitor가 많이 생김.

- H2 첨가는 안정한 HF 형성으로 F를 제거하여, F/C 비율을 줄이며 SiF4 형성을 늦게하여 식각속도를 늦춤

=> 낮은 F는 CF2, CF3 농도를 높이고 Fluorocarbon polymer를 촉진 시킴

- H2 첨가는 SiO2/Si의 선택비를 증가 시킨다.

(측벽 Polymer의 증가로 inhibitor 발생, 수평 표면은 충분한 에너지로 Ion bombard 식각

- H2 너무 많으면 Si 표면에 충분한 O2가 없어서 Si 식각 X

- F/C가 너무 크면(Polymer 두꺼우면) 식각X, Deposition

contents.kocw.net/KOCW/document/2014/Chungbuk/parkkeunhyung/11.pdf

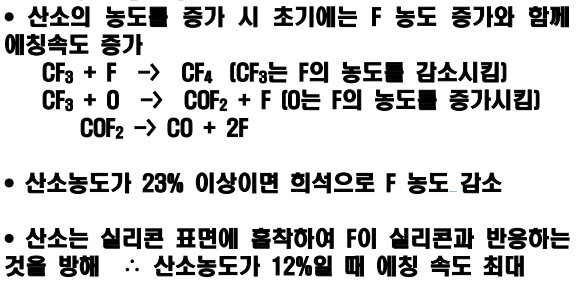

[Case 2 : F가 많은 경우-Etch]

- 식각 속도 증가

- Polymer 형성 감소 -> 등방성

- Si 식각시 SiO2에 대한 선택비 좋음.

(C가 많은 경우 SiO2 식각시 Si에 대한 선택비 좋음)

* O2 첨가

- O2 많으면 PR이 Slope 진다.

- O2 많으면 Sidewall oxide -> 비등방성

■ Dry Etch 종류

| 식각막질 | Etchang Gas | 반응 생성물 |

| Si, SiO2, SiN | CF4, SF6, CHF3, NF3 | SiF4 |

| Si | CF4, CCl2F2 | SiCl2, SiF4, SiCl4 |

| Al | BCl3, CCl4, Cl2 | AlCl4, AlCl3 |

| PR | O2, O2+CF4 | CO, CO2, H2O, HF |

| Metal(Silicide) WSi2, TaSi2, MoSi2, CoSi, NiSi |

CF4 , CCl2F2 |

1) SiO2 Etch

① SAC Etch (Self Align Contact)

- Contact 저항 확보

- High selectivity ( vs Nitride = 20:1 이상)

- Contact hole을 define 하는데 문제가 되는 photo align 한계 극복 위해.

② Contact Etch

- Contact 저항 확보

- Contact poin 별 etch target : 선행 etch 도달 후 overetch에 따른 고 선택비에 의한 내성

(먼저 원하는 목적지까지 간 애는 버텨줘야함, CD는 같아야함)

- Hole CD Control(CD동일해야 한다.)

③ IMD Etch (Inter Metal Dielectric)

- Vertical Profile

- Over etch optimize

: polymer 완벽 제거로 저항 문제 없어야하는 것이 중요

: 하부 Metal의 TiN Cap 남겨야 함. (TiN / Al / Barrier Metal)

- Hole CD Control : W/F내 위치별 구조별 CD의 일관성

2) Poly Si Etch (Gate) => vertical 이 중요!! Device 특성 영향 多

- Hard mask (Si3N4) 식각 -> Ashing (PR 제거) -> WSi/ Poly 식각 (Cl2, HBr,O2,N2사용-고선택비/CD 관리 중요) -> Light etch

- Poly Si 저항 높다 (doped Si) (WSi + Poly Si => Gate poly)

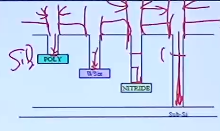

3) Metal Etch

- Barrier Metal (BM)

- Capping Metal

- Al-> Cu 다마신

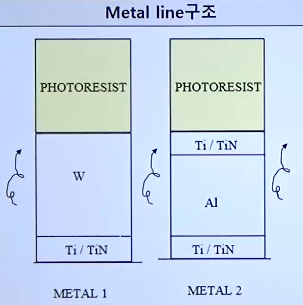

4) STI Etch (Si)

- PR, Hard Mask(Nitride) etch

- 보통 3000~5000Å

- Nitride는 인산 Wet strip

5) Silicide etch

- 내화 금속 : WSi2, TiSi2, MoSi2, TaSi2

- Good vertical etch profile (비등방성!)

- Good selectivity over oxide (>10)

(Gate oxide etching시 선택비 ~150 이상)

- Etch Rate of silicide는 polysilicon의 etch rate와 거의 비슷

- Source/ Drain쪽도 Silicide

※ Polymer 제거 공정

① 열에 의한 polymer depo

- 온도에 의해 polymer가 기체 상태를 유지하면서 진공 배기에 의해 제거

but, 온도 낮은 부위에서 depo 많이 된다.

② 온도 구배 의한 polymer depo

- 상대적으로 차가운 부분에 많은 polymer depo

- 온도가 무조건 높다고 좋은 것은 아님 -> 높은 온도에 의해 PR 경화 등 다른 문제 발생 가능성

- 온도 구배에 차이를 두면 온도가 균일해지는 경향으로 진행 (by 열역학 법칙)

③ Chamber 구조에 의한 polymer depo

- Polymer 달라 붙어.. Particle Source!!!!!!!!!!!!

- 장비 구조 중에서도 각진 부분 및 틈새 등에 Polymer가 잔류할 가능성이 크며 Gas 흐름의 와류 또는 Back-Stream 등에 의해 Polymer 위치가 결정된다.

- Chamber 내부 표면의 거칠기 (roughness)등에 따라서도 Depo 정도 및 위치가 달라진다.

- Chamber의 크기 및 Vacuum line 크기에 따라서도 Polymer Depo 정도가 틀려지며

Chamber Conductance에 의해서도 크게 좌우 된다.

* TCP-9400의 경우 Poly Etcher

- Polymer depo 정도는 M-501AWE(Hitachi)에 비해 적음

- 구조적으로 Wafer와 Polymer depo가 심한 구동부와 근접하여 있어서 와류 및 Back Stream 등에 의해 Wafer 위에 이물 형성이 많이 된다. -> Wafer와 구동부 간의 이격(거리)을 크게 하여 구조를 바꾼다.

■ Cleaning 공정

1) Particle

- 화학적 : APM(SC-1) : NH4OH : H2O2 : H2O (알칼리성)

- 물리적 : 초음파

2) 금속

- SPM (Piranha) : H2SO4 : H2O2

- HPM (SC-2) : HCl : H2O2 : H2O (산성)

- DHF : HF : H2O

- 건식 : Cl2 + light

3) 유기물

- SPM (Piranha) : H2SO4 : H2O2

- APM(SC-1) : NH4OH : H2O2 : H2O (알칼리성)

- 오존 첨가 초순수

- 건식 : UV/오존, 산소 플라즈마

4) 산화막(불산)

- DHF : HF : H2O

- BHF : HF : NH4 : H2O

- 건식 : HF 증기, 초고진공, 고온가열 초임계

'반도체 공부' 카테고리의 다른 글

| [Etch 공정 심화 5] Etch 장비, 불량 사례 (0) | 2021.03.28 |

|---|---|

| [Etch 공정 심화 3] 플라즈마 종류와 응용(Feat.Dry Etch) (0) | 2021.03.27 |

| [Etch 공정 심화 2] Etch 공정의 목적과 장단점 (Feat.플라즈마) (0) | 2021.03.26 |

| [Etch 공정 심화 1] Etch 공정의 정의와 용어 (0) | 2021.03.12 |

| [Photo 공정 심화3] (0) | 2021.02.24 |